Design & Analysis

ACS-A has a state of the art facility for composite design and analysis.

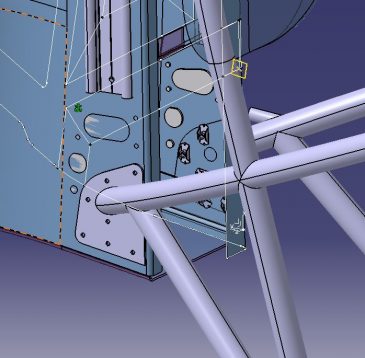

We conduct design and analysis of composite structures of any size and complexity, specialising in dynamic simulation of crash and impact events.

In addition, our specialised expertise in conceptual design, composites optimisation, flow simulation, impact and fire behaviour modelling has given a number of clients a competitive edge in their respective markets and applications.

Our customers obtain the maximum benefit of using composites via access to our in-depth knowledge of material characteristics, manufacturing processes and the means to leverage them in a cost-effective manner.