Manufacturing & Assembly

ACS-A has in-house capability for high-variation low-volume, niche application advanced manufacturing of composite products and assemblies.

In addition to manufacturing prototype and test components, ACS-A has been contracted to develop and supply advanced composite structures and assemblies for highly demanding, safety-critical applications.

We are also able to provide independent advice on the best combination of materials and process for your composites application, including assistance with the development of new materials.

ACS-A has in-house capability to design and manufacture rapid low-cost tooling, for prototyping and manufacture of high-accuracy, prototype and low-volume production components.

Services

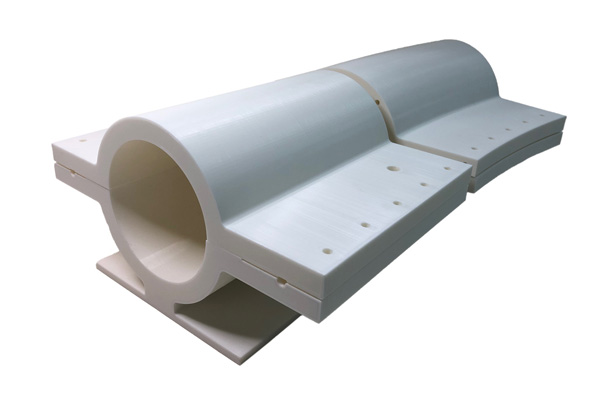

Tooling Design and Manufacture

ACS-A has in-house capability to design and manufacture rapid low-cost tooling, both for prototyping as well as rapid manufacture of high-accuracy, low-production-run components.

This enables the incorporation of low-cost manufacturing concepts into the product design process and fast turnaround of tooling to support the product development process.

In particular, we have experience in:

- Tooling and mandrel design

- Thermal profile modelling

- Prediction and incorporation of cure distortion

- Assembly jig design

- Test jig design

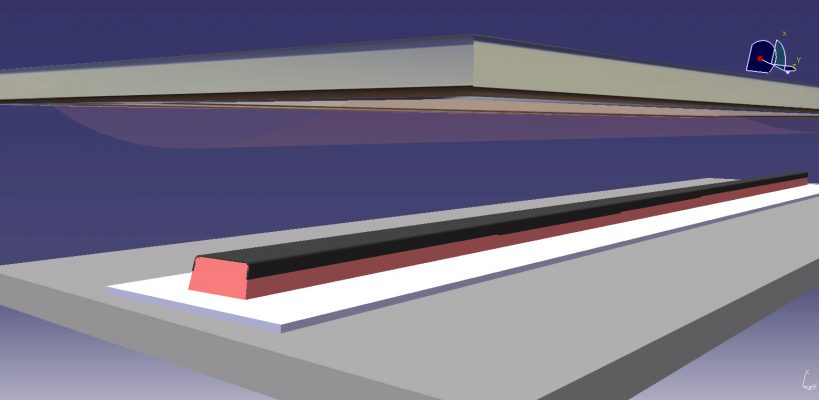

Advanced Manufacturing

Whether you require a new component or wish to improve the manufacture of existing products, ACS-A has the capability to move your product a step ahead of the competition by incorporating the latest developments.

ACS-A has in-house capability for low-volume, niche advanced composites manufacturing of products and assemblies. As a result, we are able to offer customers a complete “one-stop-shop” solution for the development and supply of advanced composite structures and assemblies. This approach is a more cost-effective and faster route to market, maximising the benefits for participating businesses.

We have experience in a large variety of composites manufacturing processes, including:

- Autoclave curing of prepregs

- Oven curing of out-of-autoclave prepregs

- Resin transfer moulding (RTM)

- Vacuum assisted resin infusion

- Pultrusion

- Diaphragm forming

- Thermoplastic forming

- Non-destructive inspection (NDI)

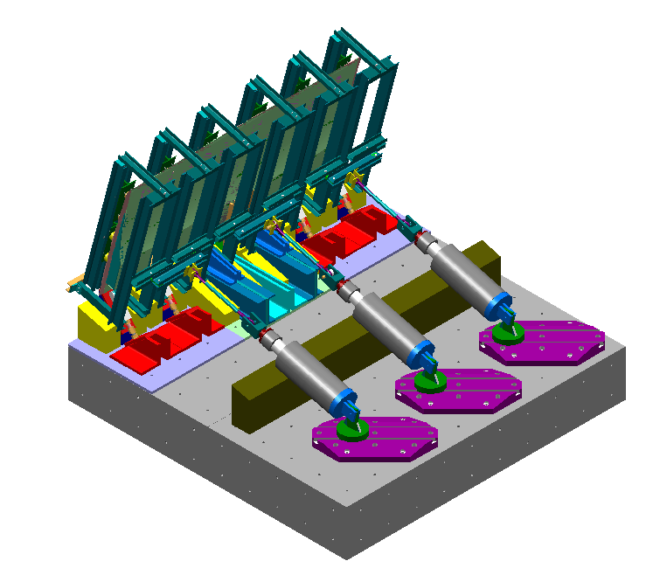

Assembly

ACS-A has the unique capability to assemble composite and metallic components with high accuracy and attention to detail.

This has been used for a number of applications including delivery of aircraft structures and other safety-critical products.

Processes include:

- Composites machining and drilling

- Surface preparation

- Adhesive bonding

- Fastening

- Thermoplastic joining / welding

Additive Manufacturing 3D Printing

ACS-A has Industry 4.0 Additive Manufacturing (3D Printing) capabilities, both for composite production and rapid prototyping. Utilising stat-of-the-art FDM (Fused Deposition Modelling) printers, producing high tolerance parts from a wide-range of thermoplastics.

Our engineers are able to print a wide range of thermoplastic materials for project production and tooling.

Capability highlights:

- Low-volume complex components

- Rapid Prototyping and Production

- Tooling for composite manufacturing

Large format FDM Printer parameters:

- Dual Extruders with 0.2 to 1 mm nozzles

- Layer Height 0.01 mm

- Volume 305 x 305 x 605 mm

- Materials include ABS, PLA, Polycarbonate, Nylon and Carbon fibre reinforced