Product Development and Testing

ACS-A is able to accelerate the development process by coupling advanced simulation with experimental testing and validation.

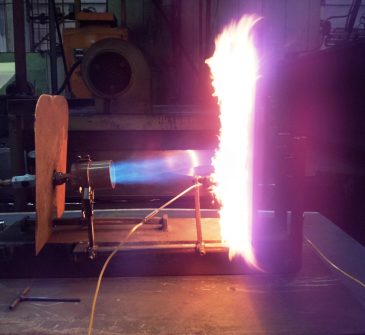

With a well-equipped facility for manufacturing and testing small-scale composite components, as well as access to a network of partners for large-scale development and verification, we are able to successfully complete a large number of development projects.

Our experience in the use of modelling tools to predict material and component behaviour during manufacturing enables production to tighter tolerances with better repeatability. This reduces experimentation during the design process, cutting the development time and cost considerably.