Inspection & Repair

ACS-A is at the leading edge of inspection and repair of composites, with unique expertise in new technology implementation.

We have a team of engineers and technicians with specialist skills and proven experience in inspection and repair of composites of aircraft and transport components as well as fatigue critical structures within the renewable energy market.

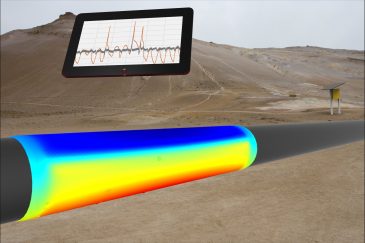

ACS-A staff have a record of success in the design and implementation of repairs for composite structures and metallic structures. Examples include the inspection and repair of damaged storage tanks, pipelines, wind turbine blades, aircraft, helicopters and marine structures.