Satellite communication (satcom) plays a vital role in our everyday lives and to industries such as aerospace, defence and telecommunications. One of the key components of satcom systems is the antenna reflector assembly which must be highly manoeuvrable for optimal continuous coverage. The next critical structural parts of the satcom system are the azimuth arms, which support the antenna load and enable 360-degree rotation with precise and rapid response manoeuvrability.

Advanced Composite Structures Australia (ACS Australia), in partnership with EM Solutions, is leading the way in the development and series production of state-of-the-art carbon fibre composite azimuth arms for ship-borne satcom. The partnership between ACS Australia and EM Solutions is a testament to the strength of Australian manufacturing and highlights the benefits of industrial collaboration in driving sovereign capability.

Together, ACS Australia and EM Solutions have developed an innovative all carbon fibre composite azimuth arm that offers a simplified one-piece, corrosion resistant and light-weight alternative to metallic constructions. Carbon fibre composites offer unparalleled advantages over traditional materials, including higher strength-to-weight ratio, corrosion resistance and greater durability in fatigue environments, an important requirement for Australian Defence applications.

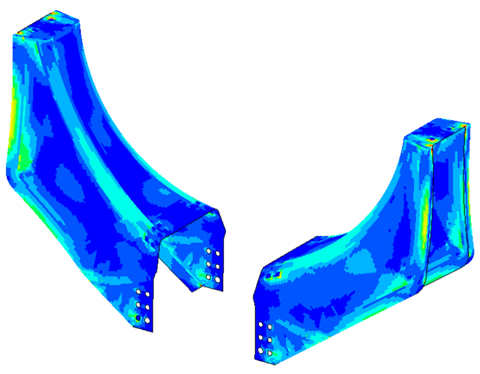

The new single-piece design offers significant improvements over traditional metallic azimuth arms in terms of weight, assembly time and maintenance cost. ACS Australia engineers validated the novel design with static and dynamic finite element structural analysis to meet varying load conditions and deliver an all-carbon fibre epoxy composite structure optimised for both manufacture and ease of installation for end-user application.

The carbon fibre composite design meets all static and dynamic requirements, including the high blast requirements of topside naval structures. The optimised design reduces overall weight by approximately 65% compared with the metallic design and achieves a significantly reduced part count (approximately 50 parts less), resulting in far fewer fittings and fasteners being required. This advanced design helps to reduce top-side weight for navy vessels, as well as reduces power consumption and sizing requirements for sub-systems due to the light-weight composite construction.

EM Solutions is proud to share that the first new King Cobra product is now installed, commissioned and sailing on Navy vessels. The EM Solutions King Cobra is a two-metre class naval maritime satcom terminal, with full extended Ka Band and simultaneous X-Band coverage and enabled to access GEO, MEO, HEO and LEO satellite constellations. The King Cobra is a robust tracking terminal offering both military and commercial bands in the one terminal that is designed in Australia and trusted by the Australian Border Force, the Royal Australian Navy, allied navies and the US Government for reliable offshore military satellite communications.

To learn more about the project or to get in touch with the ACS Australia team, please don’t hesitate to contact us!