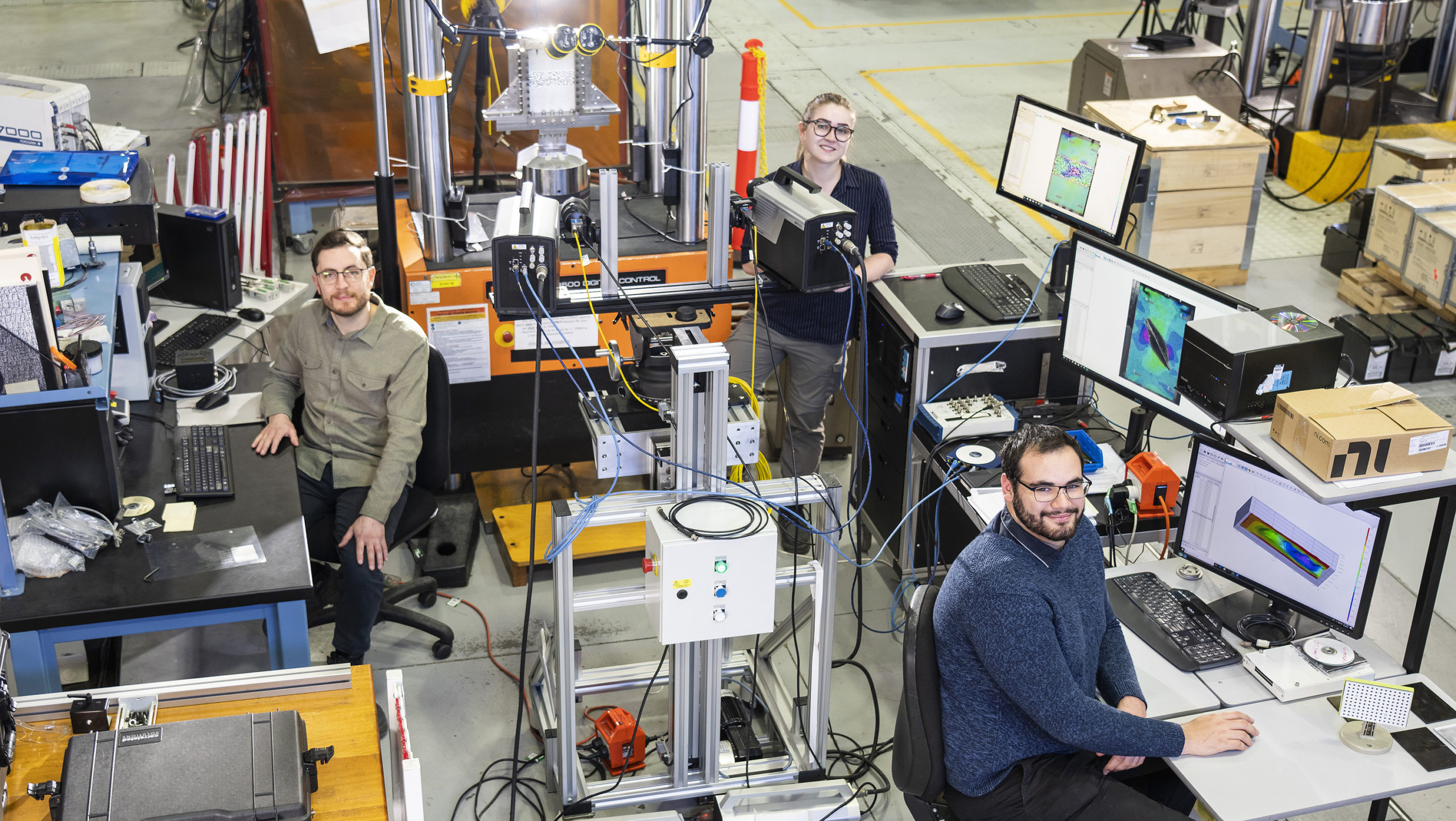

📸🏁 Using ultra-high-speed cameras with a randomised speckle pattern applied to the surface, Advanced Composite Structures Australia | ACS-A senior engineering technician Patrick Frezza, with engineers Claire Dunne and Lachlan Burgess-Orton (pictured) have been supporting Defence Science and Technology Group (DSTG) in the development of a Digital Image Correlation (DIC) technique to capture at up to five million frames per second the three-dimensional strain data of composite panel surfaces as they fail under compressive loading.

This structural analysis provides insight on how to best manage aircraft composite structures and how the surface handles in-service impact damage (e.g., dropped tools during maintenance and bird strikes during flight). This is in preparation for entry into service of the MQ-4C Triton Unmanned Aircraft System (UAS) to be operated by the Royal Australian Air Force.

To learn more about how this work is helping Defence visit: https://lnkd.in/gU4cYHqG

For greater in-depth understanding you may read the AIAC20 conference paper, presented at the 20th Australian International Aerospace Congress, 27-28 November 2023, Melbourne:

The test set up developed allows for both highspeed DIC (of the failure) and low speed DIC (of the entire test) to be captured concurrently on the same test.

The specimen is base painted white. The team precision laser cut a speckle pattern, which is optimised for the correct speckle size, on a sheet of mylar film to create a stencil. The team then glues the stencil over the white specimen and airbrush with black paint to create the speckle on the surface before peeling the stencil off.

Image source: DSTG, Department of Defence