Melbourne, Australia; Mon, 7/SEP-2020.

Advanced Composite Structures Australia (ACS-A) continues to invest in Industry 4.0 capabilities, which includes an Additive Manufacturing FDM (Fused Deposition Modelling) 3D Printer and, more recently, a CNC MultiCam System.

This has enabled our engineers to revolutionise the way they design and manufacture critical components, connecting the digital work environment of Computer-Aided Design (CAD) directly to the physical article being produced in a single-step. This allows ACS-A to conduct more development work in-house and replaces some traditional labour-intensive manufacturing processes for:

- Short run complex components

- Rapid Prototyping and Production

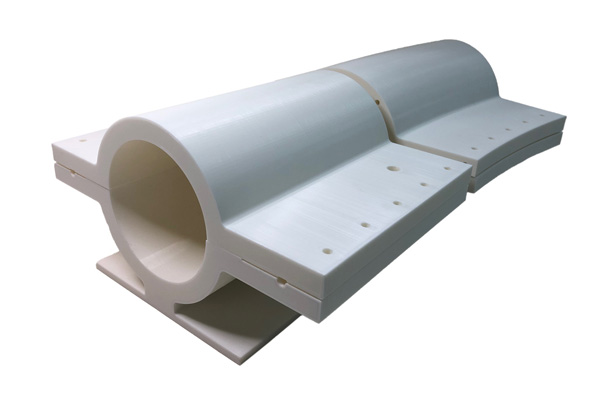

- In-house tooling for composite manufacturing

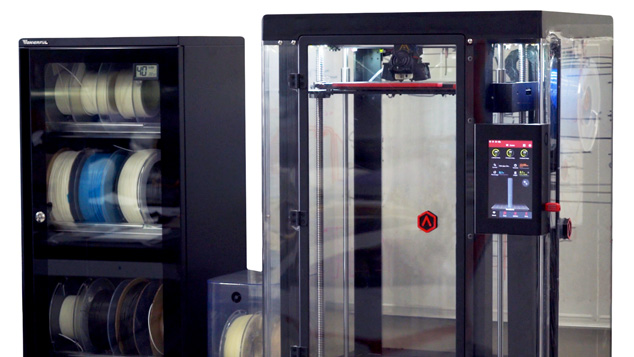

ACS-A is utilising an industrial large-format 3D printer, Raise 3D Pro 2 Plus, for high resolution rapid production and prototyping, with the following capabilities:

- Dual Extruders (for two types of materials and colours), with 0.2 to 1 mm nozzles (layer height 0.01 mm)

- Maximum Component Size: 305 x 305 x 605 mm

- Potential use of a variety of materials (up to 300°C) including ABS, PLA, PVA, HIPS, TPU, TPE, ASA, PETG, Polycarbonate, Nylon, Carbon short fibre reinforced and Glass fibre Infused

Our 3D Printer is cloud connected with camera for monitoring (IoT capable), allowing our designs to be rapidly produced within hours without physical supervision, which permits more time to focus on design optimisation. Also, as CAD model designs can be sent remotely to the printer, this allows further cost reduction, as the requirement for manufacturing work instructions is removed.

These new manufacturing capabilities enable our engineers to manufacture short-run components for projects and rapidly prototype concepts, making work more efficient, and with the reproducibility of automation.

Additive Manufacturing brings in-house capability of producing parts and tooling for composites, reducing the reliance on lengthy supply chains. This is more important now than ever, as we grapple with global impacts on manufacturing and supply chains.

“Companies that [are] early adopters of 3D printing will be most able to respond quickly…in a crisis”, “a very significant growth and future for 3D printing in Australia…to rebuild manufacturing capabilities”.

3D printing to thrive during COVID-19 and beyond – Manufacturer’s Monthly, July 2020

Additive Manufacturing is a transformative approach to industrial production, and compliments existing composite material manufacturing, enabling the creation of lighter, stronger parts with more complex geometry:

- Quick response and faster Concept-to-Market, minimising lead times

- Customisation and flexibility in prototyping

- Reduced waste, only using material we need

- Automated builds with high repeatability

- Requires fewer tools to produce components

- Faster production, and simpler with fewer process steps

- Lower carbon footprint, reducing supply chain and transportation needs

“A recent example of our use of Additive Manufacturing was a Camera Housing designed and manufactured for off-shore oil & gas applications. Traditional manufacturing methods would have involved the assembly of multiple parts; 3D Printing allowed us to create a design using just two parts.”

Rodney Thompson, Engineering Manager at Advanced Composite Structures Australia

“Often in engineering design it is difficult to convey physically what a final concept will look like from a 3D CAD model or 2D image. For an Animatronic Creature project involving the manufacture of carbon fibre composite components with complex geometric shapes, we used a one-tenth 3D printed scale model to show our customer at meetings.”

“Additive Manufacturing enables us to print parts to scale, using this to accurately convey to our customers what the final design will look like.”

Rodney Thompson, Engineering Manager at Advanced Composite Structures Australia

It allows engineers and designers to get a better understanding when they can touch and feel the 3D concept, without needing to visualise it from a 2D image. This makes concept and development iterations more productive, bringing the final product closer to delivery.

“Our 3D Printing helps to bring down costs and reduce delivery times for our customers”

Michael Vuong, Engineer at Advanced Composite Structures Australia

To learn more about our 3D printing and rapid prototyping capabilities and to see what is possible, please listen to our Additive Manufacturing lead engineer, Michael Vuong, in this short video: https://youtu.be/byDVw40qjp0

We look forward to developing more novel designs and challenging the conventional in manufacturing as we leverage industry 4.0. Whether customers need a rapid turnaround on a design prototype, or their project involves complexity and unique short-run components, our additive manufacturing capabilities are ready to support.

The team at ACS Australia specialise in design and manufacture of light weight composite materials, leveraging Industry 4.0 technologies, including Additive Manufacturing and CNC Automation. If your business is looking for a competitive edge please contact our team today!