Advanced Composite Structures Australia (ACS Australia) has been awarded a Federal Government Sovereign Industrial Capability Priority (SICP) grant to assist in the funding of a new $400k project to further advance the production capabilities of Ultra-High Temperature (UHT) composites for hypersonic vehicles. This contributes to a total investment for the past year of over $1M.

“This grant supports ACS Australia’s investment into ultra-high temperature composites manufacturing, ensuring we remain at the forefront for the supply of componentry for hypersonic and space vehicle applications. As we scale production and grow our team, we look forward to offering this expanded sovereign capability to meet the demands of our partners.“

Paul Falzon, General Manager of Advanced Composite Structures Australia | ACS-A

Part of the strategic growth for ACS Australia has included moving to a larger facility in Port Melbourne (new address: 19 Rocklea Drive, Port Melbourne, Victoria, Australia), which has increased the engineering and design office footprint as well as ACS Australia’s capacity to concurrently deliver on a number of series composite production programs for civil and defence customers.

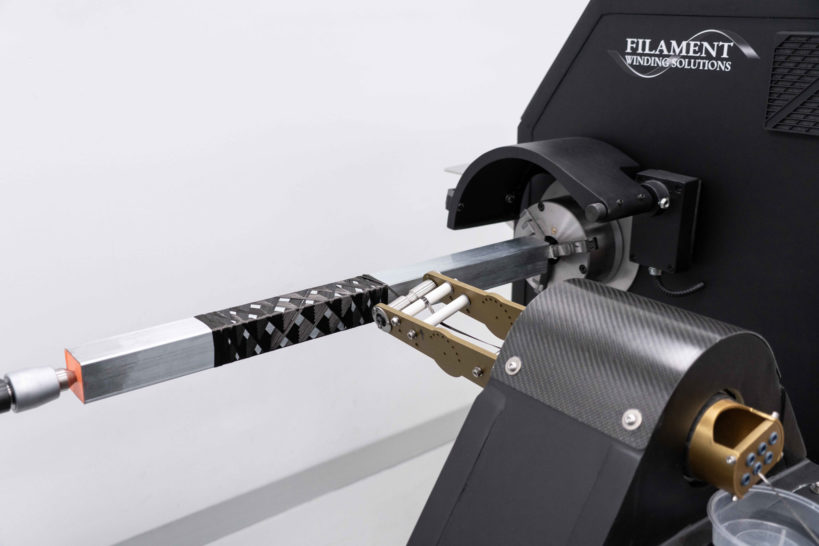

The investment into the new facility has brought with it the acquisition of new equipment, including a CNC ply cutting machine, bespoke advanced filament winding equipment and a 3D scanner for geometric verification of parts and tooling.

The filament winder enables hypersonic structures to be manufactured with greater precision in an automated process, reducing lay-up times significantly and eliminating manually intensive manufacturing.

To maintain its commitment to producing high precision, complex structures, ACS Australia has integrated an Artec Eva 3D Scanner into the quality control process. This tool streamlines geometric verification and bolsters existing quality management practices.

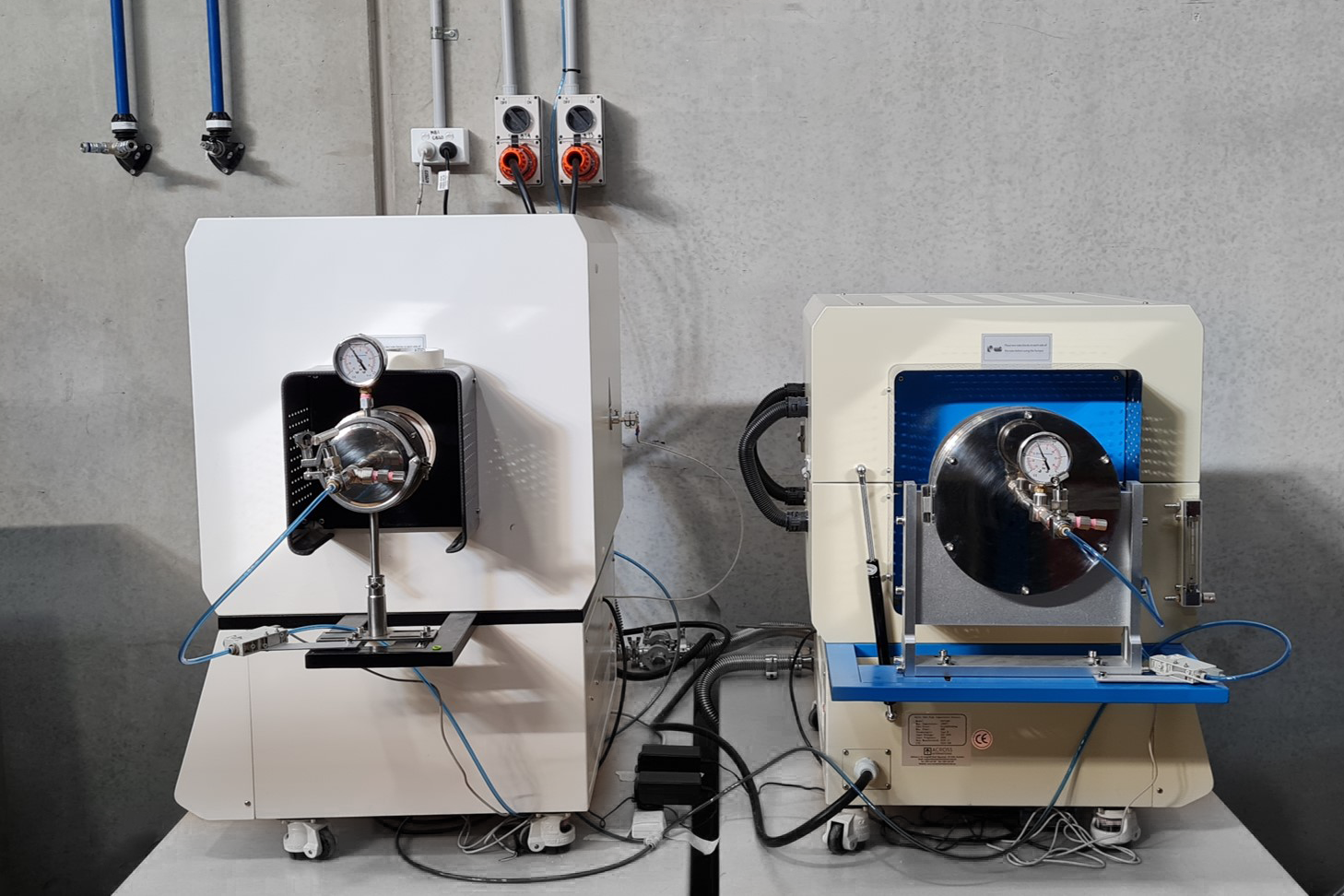

A highlight of ACS Australia’s specialised equipment, specific to the development and manufacture of ultra-high temperature fibre composite materials, are two furnaces capable of temperatures up to 1,200°C and 1,700°C.

Complementing ACS Australia’s enhanced capabilities is the latest acquisition of an electromechanical MTS 100 kN Universal Testing machine. This helps speed up design and manufacturing decisions and processes by bringing coupon testing in-house.

The facility and equipment are fully operational now and production of components for defence, renewable energy, civil and aerospace projects are underway. ACS Australia is excited to engage with partners and clients who wish to explore our capabilities further.

Update August 2024 – Thank you to AMTIL for sharing this in their AMT Magazine August/September edition pp. 56-57: https://amtil.com.au/amt/2024-amt-magazines/amt-aug-sep-2024/

We encourage interested parties to contact us to discuss how our expertise in composites technology can benefit their projects.